P 20-50 Å S. Pressure swing adsorption PSA has become a viable alternative to cryogenic distillation for the separation of oxygen from air with the development of advanced adsorbents like zeolites.

Parametric Study And Control Of A Pressure Swing Adsorption Process To Separate The Water Ethanol Mixture Under Disturbances Sciencedirect

The optimal design of pressure swing adsorption systemsII.

. Assume one minute cycle time adsorption regen. AgA zeolite Design 3. Interim guidance 8 June 2020.

Product Nitrogen flow rate required 7 Nm3hr O2 Oxygen in product 00677 Ar Argon in product 0933 Adsorption material properties 2. Carnegie Mellon University. Simultaneously Column 2 is saturated with adsorbed oxygen at the work- ing pressure and is vented to the atmosphere blowdown.

Pressure swing adsorption PSA process is a wide operati ng unit for separation and puri -. 229 201b2 1 lul lvlAy where in the transient analysis. Adsorption Depressurization Regeneration Repressurization To provide continuous hydrogen supply mini-mum 4 adsorber vessels are required.

A detailed mathematical model is developed which captures the hydrody-namic mass transfer and equilibrium effects in detail to represent the real PSA operation. Adsorption O₂ production Desorption evacuation. G 600-800 m2g Synthetic polymers or resins.

Both analyses give different values of D or D in different directions each of the form. Is degree of gas saturation. This thesis is concerned with the design operation and control of pressure swing adsorption PSA systems employing state of the art system engineering tools.

24 Wheels in parallel to provide required. Technical specifications for Pressure Swing Adsorption PSA Oxygen Plants. Oxygen is an essential medicine required at all levels of the health care system.

According to the experimental adsorption isotherms and kinetic rates of adsorption in porous media the isothermal mathematical model of PSA system. 1971 A simple method Yl. 1c Langmuir For gases q vs.

Adsorbent circulation rate 1800 tonnesmin. The pressure swing adsorption process has four basic process steps. Working capacity 13wt 03 molekg adsorbent.

The column diameter and cycle time was held constant. Plots of q vs. Ive designed the adsorption column.

A Gas Separation Purification Process Pressure swing adsorption is an adsorption-based process that has been used for various gas separation and purification purposes. The Achilles Heel of Adsorption processes. The figure on page 6 shows the combination of the sequen-ces of four adsorber vessels as a pressure-time-diagram.

Fica tion of gas es that operate s based on. Partial pressure dewpoint or some other form of concentration is plotted versus temperature or inverse absolute temperature at specific extents of loading usually as mass percent. Medium scale capacity Safety Cost savings An analysis of 4 designs using zeolites LiAgX and AgA in the PSA adsorption beds was performed.

In this study we present a method to estimate the breakthrough time of a commercial pressure swing adsorption process. And the process design. Design and Optimization for Pre-Combustion Carbon Capture Alexander W.

Variability of the tail gas pressure and composition. Carbon steel is the typical material of construction for the entire PSA system although stainless steel is some-times used for chemical feeds. Design 1 LiAgX zeolite Design 2.

The notations on that illustration are used later to explain aspects of termperature swing adsorption TSA gas drying. C gives constants Eg. D 121 u 1 - c D 12 VAY 1 - cy but in the steady-state analysis D 112 uh D UZ VA.

Separation in these processes depends on the ability of one. Y2 transformed dimensionless distances for the calculation of effectiveness factors. Other lines and headers may exist for pressurization and purging of the vessels.

Design and Optimization of Pressure Swing Adsorption Separation Process of MNP-10 LN2 Plant IJSRDVol. Pressure swing adsorption PSA is widely used for hydrogen puri cation. 1000 Megawatt power Stn.

42 Pressure swing adsorption system limit. 500kg mole CO 2 min. As for my 3rd Year Design Project I was given a task to design a syngas production plant and towards the end of the process we are going to use the pressure swing adsorptionvacuum swing adsorption to remove the carbon dioxide.

Only high quality medical-grade oxygen should be given to patients. The amount of carbon dioxide that is removed from the unit per day is 2352kg. 2g3 Before the hydrogen produced by this reforming process is delivered to the consumers it must be sent to a puri cation unit that removes any unconverted methane and steam along with carbon monoxide and carbon dioxide 4 3.

Pressure swing adsorption PSA oxygen generating plants are a source of medical-grade. Freshly purged and at a low eg atmospheric pres - sure Column 1 is quickly pressurized with an air feed stream to the systems selected working pressure. For a book deals with the practical design of adsorption bed Adsorption technology and design 1998 is a good one and for modeling or equations Pressure swing adsorption 1994.

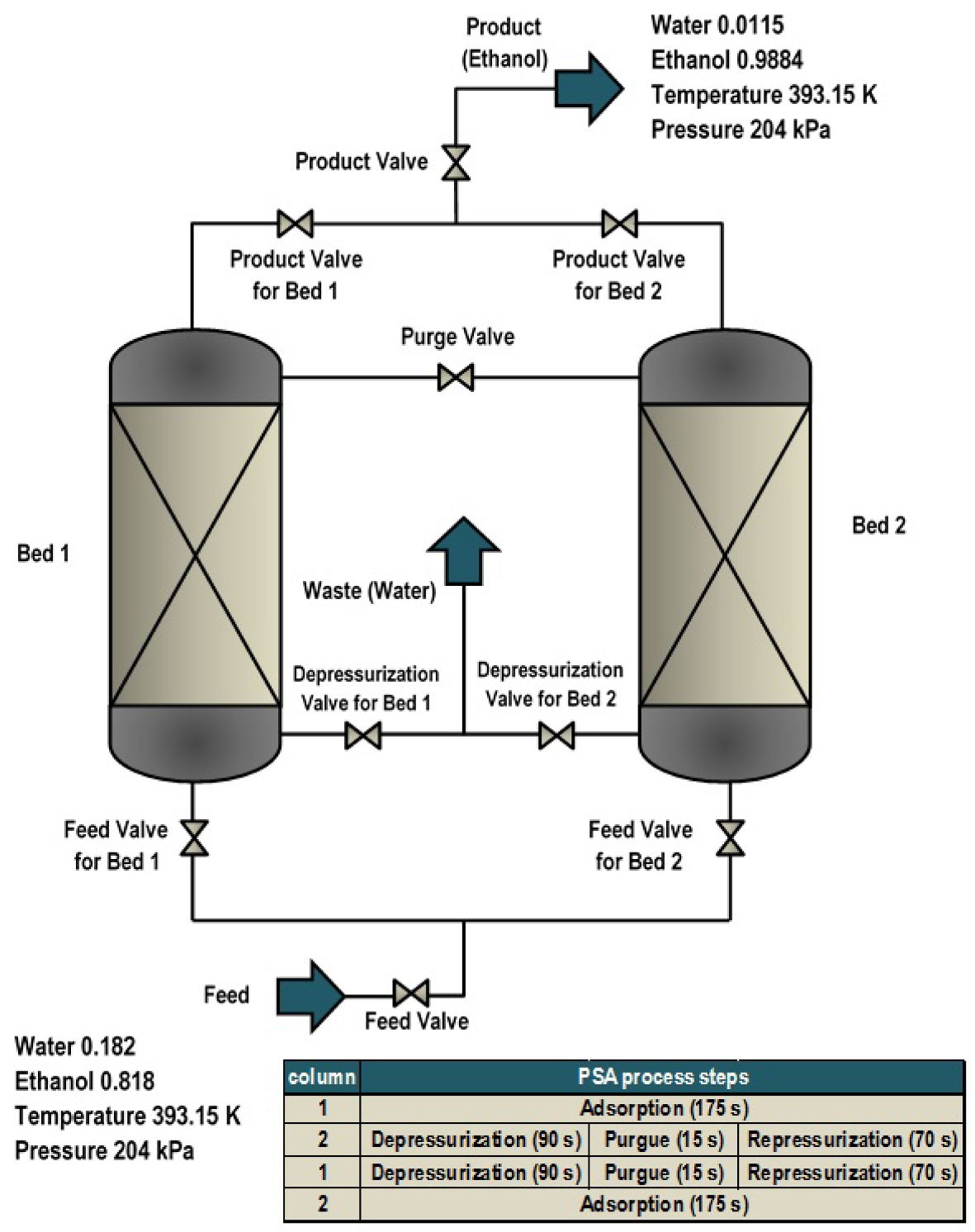

A specific example is shown in Figure 2. Using the Pressure Swing Adsorption PSA technology one can introduce a flexible solution in pre-existing gas-processing units to deal with new marked demands as for example a C 3 free gas composition to be. P a g e 2 9 Indicators of a PSA Process Performance.

To reduce energy consumption the pressure is equalised between the production overpressure and regeneration vacuum steps. Swing between overpressure and vacuum occurs Vacuum Pressure Swing Adsorption. Differences between gas and liquid adsorption.

Pressure Swing Adsorption PSA will be used in the design for. Rotary Wheel Contactor diameter 10m depth 10m. Each adsorber undergoes a cyclic process consisting of.

Up to 10 cash back Adsorption processes with activated carbons can be used to remove heavy hydrocarbons from a natural gas flow. For constant pressure steps adsorption and purge the total concentration of the fluid remains constant in the bed thus the total mass balance will be 2 C v z 1ε ε i1 N q i t 0 while for pressure changing steps the total mass balance is 3 v z 1 P P t 0 where it is assumed that the pressure drop in the bed is negligible. The accuracy and reliability needed for industrial design 7-12.

Processes Free Full Text Adsorption And Separation Of The H2o H2so4 And H2o C2h5oh Mixtures A Simulated And Experimental Study Html

Scielo Brasil Simulation And Optimization Of An Industrial Psa Unit Simulation And Optimization Of An Industrial Psa Unit

Parallel And Series Multi Bed Pressure Swing Adsorption Processes For H2 Recovery From A Lean Hydrogen Mixture Sciencedirect

H2 Pressure Swing Adsorption For High Pressure Syngas From An Integrated Gasification Combined Cycle With A Carbon Capture Process Sciencedirect

Pressure Swing Adsorption Process Animation Psa Process Youtube

Integrated Design And Control Of Pressure Swing Adsorption Systems Sciencedirect

0 comments

Post a Comment